Discover effective cost cutting strategies that boost efficiency without compromising product quality. Explore streamlined operations, technological innovations, vendor negotiations, employee development, sustainability practices, and quality monitoring for sustainable business success.

In today’s competitive market, optimizing operational expenses without compromising product quality is an ongoing challenge for businesses. Cost cutting isn’t merely about reducing expenses; it’s a strategic approach to enhancing efficiency while maintaining or even elevating the standards of your offerings. We, at our company, understand the paramount importance of this balance, and we’ve curated comprehensive strategies to aid in cost reduction without undermining the quality of your product.

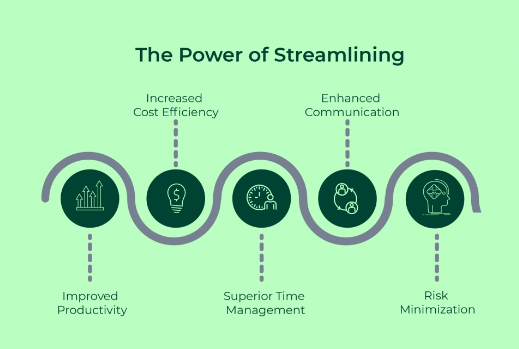

1. Streamlining Operations for Enhanced Efficiency

Efficiency lies at the core of cost optimization. By analyzing and refining your operational processes, businesses can significantly cut down on unnecessary expenses without compromising quality. Conduct a thorough audit to identify bottlenecks or redundant procedures, then streamline workflows to eliminate inefficiencies. Implement lean management principles to optimize resource allocation, reduce waste, and enhance overall productivity.

ALSO READ: Landing The Perfect Commercial Space For Your Business

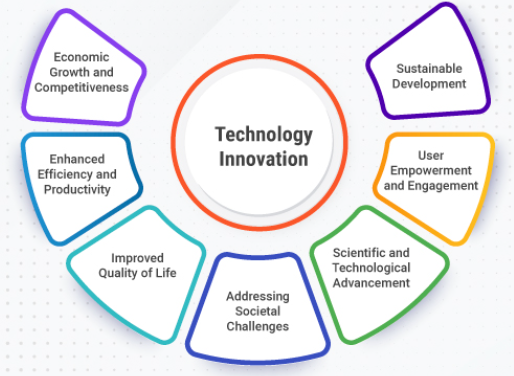

2. Embrace Technology for Innovation

Innovative technologies offer substantial opportunities for cost reduction. Invest in state-of-the-art tools and software tailored to your industry. Automation of repetitive tasks not only increases efficiency but also reduces the chances of errors, thereby preserving the quality of your product. Furthermore, leveraging analytics and data-driven insights can guide informed decision-making, ensuring targeted and cost-effective strategies.

3. Vendor Management and Negotiation

Forge strong relationships with suppliers and vendors. Negotiate favorable terms, explore bulk purchase discounts, and seek alternative sourcing options without compromising quality. Regularly evaluating vendor performance and seeking competitive bids helps in maintaining cost control while ensuring top-notch materials or services.

4. Employee Training and Development

Investing in the skill development of your workforce yields long-term benefits. Well-trained employees are more efficient, productive, and innovative. This leads to improved quality in the production process and minimizes errors, contributing to cost savings over time. Moreover, nurturing a culture of continuous learning fosters employee loyalty and retention, reducing recruitment costs.

5. Sustainable Practices for Long-term Cost Efficiency

Embracing sustainable practices isn’t just an ethical choice but a financially prudent one. Implement energy-saving initiatives, recycle materials, or optimize packaging to reduce waste. These steps not only contribute positively to the environment but also cut down on operational costs in the long run, ultimately maintaining product quality.

6. Continuous Quality Monitoring and Improvement

Maintaining product quality throughout the cost-cutting process is imperative. Regular quality checks, customer feedback analysis, and continuous improvement methodologies like Six Sigma or Total Quality Management ensure that cost reduction efforts do not compromise the value your product offers to consumers.

Conclusion

Balancing cost reduction with quality maintenance is an art that businesses must master to thrive in today’s competitive landscape. By implementing these strategies, businesses can effectively cut costs without compromising product quality. It’s a holistic approach that requires diligence, adaptability, and a commitment to continuous improvement.

Click here, to check out the latest post on Instagram.

Also read: Mastering Buyer Problem: Strategies For Effective Solutions

image source: google