Plastic is one of the most widely used materials in the world, but it also poses many environmental and health problems. Most plastics are made from fossil fuels, which contribute to climate change and pollution. Most plastics are also non-biodegradable, which means they accumulate in landfills and oceans, harming wildlife and ecosystems. Moreover, most plastics are not very durable or recyclable, which means they break easily and generate more waste.

To address these challenges, scientists at the University of Tokyo have developed a new type of plastic that is stronger, stretchier, self-healing, shape-memory, and partially biodegradable. This innovative plastic, named VPR (vitrimer incorporated with polyrotaxane [PR]), is the result of adding a molecule called polyrotaxane to an epoxy resin vitrimer, a type of plastic that can be reshaped at high temperatures1.

How VPR works: Self-Healing Plastic

Also read : Fish: Can It Rain Fish?

Vitrimers are a relatively new class of plastics that combine the properties of thermoset plastics and thermoplastics. Thermoset plastics are hard and rigid, but they cannot be melted or reshaped once they are cured. Thermoplastics are soft and flexible, but they can be melted and reshaped multiple times. Vitrimers are solid and strong at lower temperatures, but they can also be reformed at higher temperatures1.

However, vitrimers have some drawbacks. They are typically brittle and cannot be stretched far before breaking. They also have poor self-healing and shape-memory abilities, which means they cannot repair themselves or retain their original shape after being deformed. To overcome these limitations, the researchers added polyrotaxane to the vitrimer. Polyrotaxane is a molecule that consists of a linear chain with ring-shaped molecules threaded onto it. The rings can slide along the chain, giving the molecule a dynamic and flexible structure1.

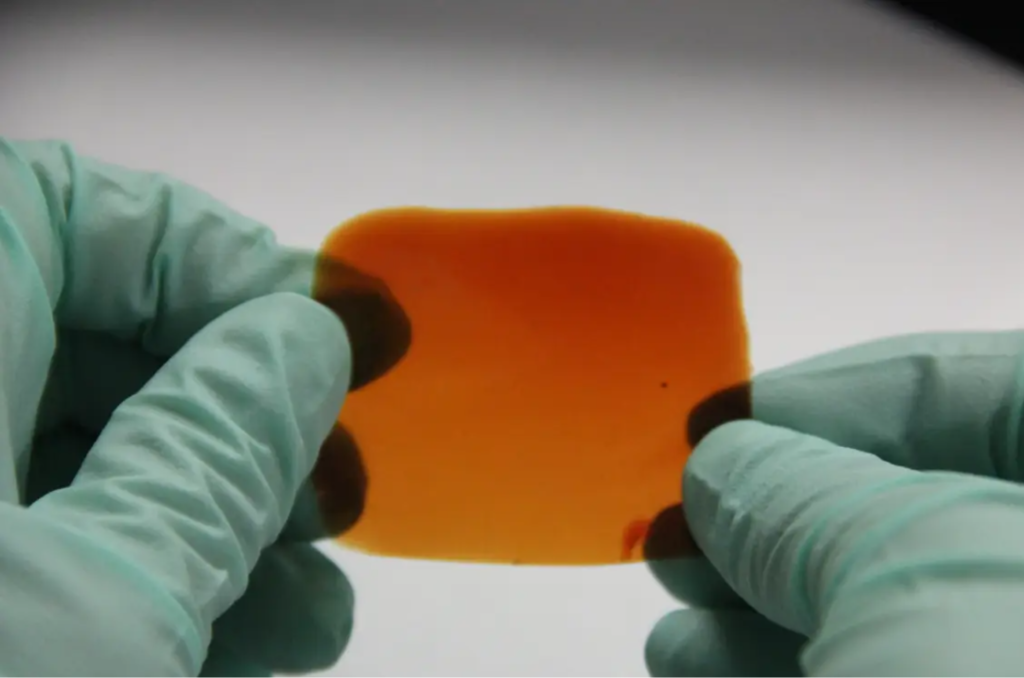

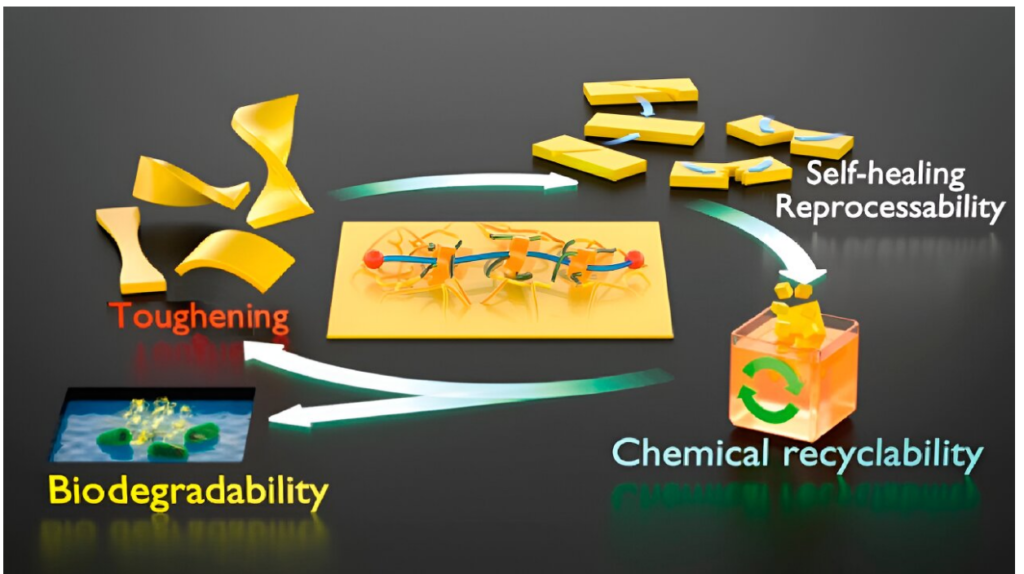

By incorporating polyrotaxane into the vitrimer, the researchers created VPR, a plastic that has enhanced properties. VPR is over five times as resistant to breaking as a typical epoxy resin vitrimer. It can also be stretched up to 27 times its original length without breaking. VPR can heal itself by applying heat, which allows the bonds between the molecules to recombine. VPR can also remember its shape and restore it after being heated, which enables it to form complex structures. VPR can be broken down into its raw components by applying heat and a solvent, which makes it easier to recycle. VPR can also biodegrade in seawater, with the polyrotaxane breaking down into a food source for marine life1.

Potential applications of VPR

VPR is a versatile and sustainable plastic that could have wide-ranging applications for various industries and fields. For example, VPR could be used for engineering and manufacturing, as it can withstand high stress and strain, and can be easily molded and reshaped. VPR could also be used for medicine and biotechnology, as it can heal itself and biodegrade in the body, and can be programmed to change shape and function. VPR could also be used for fashion and design, as it can create novel and dynamic shapes and textures, and can be recycled and reused1.

The researchers are exploring the potential uses of VPR and are working to improve its performance and functionality. They hope that VPR will contribute to the development of a more circular economy, where resources are recirculated and waste is reduced, and to the achievement of the United Nations’ Sustainable Development Goals1.

Addressing Plastic Use and Waste

It is challenging to avoid plastic despite international attempts to reduce its use and disposal. These days, technology seems to be present in practically everything we use, from toys and clothing to electronics and household goods to cars and infrastructure.Plastic’s life cycle and disposal are fraught with problems despite its usefulness. Contributing to the resolution of these issues and the achievement of several Sustainable Development Goals of the United Nations will need the development of substitutes that are more durable, more easily recyclable, or derived from ecologically benign materials.

Also read :Nuclear reactions: Are There Nuclear Reactions Going On In Our Bodies?