The Artemis II mission to the Moon’s SLS rocket booster parts from NASA have arrived at the Kennedy Space Centre. They’ll serve as important boosters that will provide significant liftoff thrust. With four astronauts on board, the Artemis II will be an important crewed test for the Orion spacecraft.

SLS rocket: Rocket booster

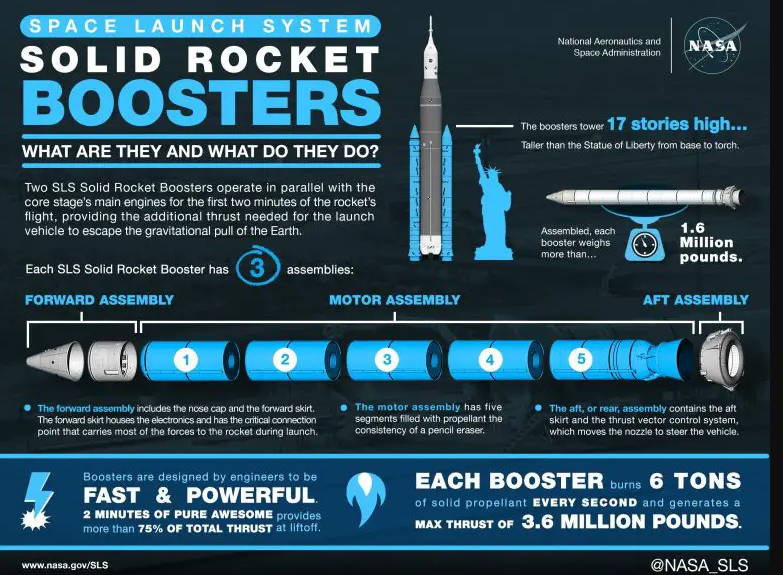

On September 25, ten booster motor segments for NASA’s SLS (Space Launch System) rocket that will help the Artemis II crew travel around the Moon arrived at the Florida facility. To launch NASA’s Artemis missions to the Moon, they will combine to form the twin, five-segment solid rocket boosters of the SLS rocket, which generates more than 75% of the total thrust during liftoff.

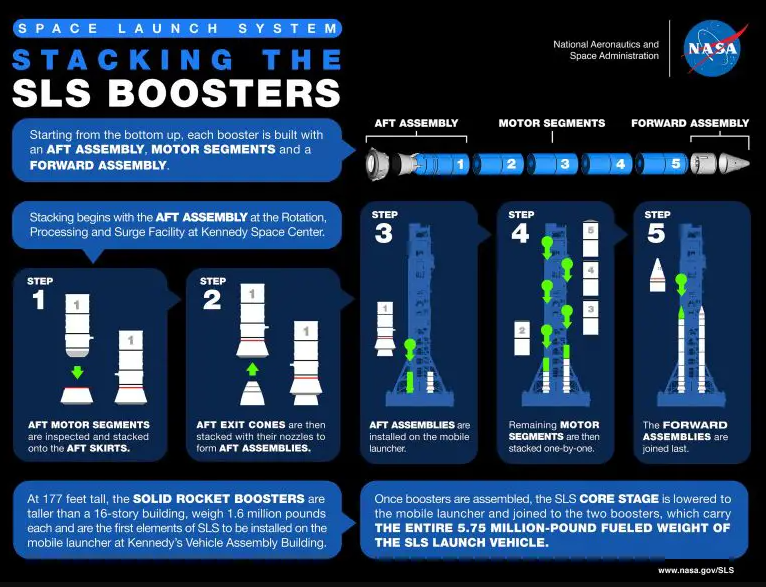

The 10 booster motor components were transported to the spaceport by rail across eight states because to their weight. As they get ready to integrate them within the Vehicle Assembly Building, teams from NASA’s Exploration Ground Systems Programme are processing each of the segments inside the space center’s Rotation, Processing and Surge Facility.

We need a bigger booster for the bold missions NASA’s Space Launch System rocket will give us the capability to achieve. This infographic sums up everything you need to know about the Space Launch System Solid Rocket Booster or SRB. The booster uses a 5-segment solid propellant motor, and the motor is the largest component of the booster. Credit: NASA/MSFC

As NASA and its Artemis partners get ready for stacking and launch preparations for Artemis II, the delivery of the SLS solid rocket booster motor segments marks a crucial turning point, according to Amit Kshatriya, Deputy Associate Administrator for the Moon to Mars Programme Office at NASA Headquarters. These boosters for NASA’s SLS rocket, which are fully stacked, are the biggest, most potent spacecraft components ever made and will help send the first astronauts around the Moon in more than 50 years.

The SLS solid rocket boosters are produced in Utah by lead booster contractor Northrop Grumman and consist of three main assemblies, with the motor section representing the bulk of the booster. Along with the boosters’ forward and rear skirt components, teams will inspect them. In order to prepare for stacking operations for Artemis II, they will turn the segments to a vertical position after that. Booster Fabrication Facility at Kennedy previously put together the top and bottom pieces of the boosters.

Two 177-foot-tall solid rocket boosters help launch NASA’s Space Launch System (SLS) rocket on the Artemis missions to the Moon. Each booster is made up of several large structures that are assembled and prepared for launch by the Exploration Ground Systems team at the agency’s Kennedy Space Center in Florida. Credit: NASA/Kevin O’Brien

The key components will be moved one at a time, when processing is finished, to the Vehicle Assembly Building where they will be stacked to create the 17-story boosters that flank either side of the rocket. Engineers and technicians will integrate the rocket’s core stage after it is finished. The four RS-25 engines in the core stage and the twin boosters of the SLS rocket work together to create more than 8.8 million pounds of thrust.

Prior to future moon trips, NASA astronauts Reid Wiseman, Victor Glover, Christina Koch, and Jeremy Hansen will go on board Artemis II, the first crewed Artemis mission, to test every system of the Orion spacecraft.

ALSO READ: Exploring the Best Hotels Near Kennedy Space Center