By covering DNA with a pure form of glass, researchers have developed a unique material that is both lighter and stronger than steel Series. This ground-breaking finding has the potential for a wide range of applications in engineering and defence because to the nanoscale glass structure and special DNA characteristics.

Researchers developed a light steel series yet strong material by combining two unexpected ingredients—DNA and glass.

The ability to create and analyse materials with great accuracy comes from working at the nanoscale. Many materials are prone to flaws and impurities that can jeopardise their sophisticated design in larger-scale manufacture and even in natural environments. They may crack under strain due to these weaknesses. This is especially noticeable in the majority of glass kinds, which contributes to the material’s reputation of being fragile.

Researchers at Columbia University, the University of Connecticut, and the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory were able to manufacture a pure form of glass and coat specialised DNA fragments with it to produce a material that was not only stronger than steel but also incredibly light. These two properties are unusual in materials, and additional study could result in inventive engineering and defence uses. The Cell Reports Physical Science journal released the findings.

DNA—The Building Blocks for Life and More

Deoxyribonucleic acid, or DNA as it is more popularly known, is the biological code that tells the cells of living things how to form, develop, and reproduce. A polymer is a stiff, elastic material class that includes plastic and rubber, and it is what DNA is made of. Material scientists have been fascinated by their resiliency and simplicity, which has led to numerous intriguing studies. Oleg Gang has spent years using DNA’s special features for materials synthesis, leading to a number of breakthroughs. He is a materials scientist at the Centre for Functional Nanomaterials (CFN), a DOE Office of Science User Facility at Brookhaven Lab, and a professor at Columbia University. A wide range of creative applications, including electronic and medication delivery, have been sparked by this new technology.

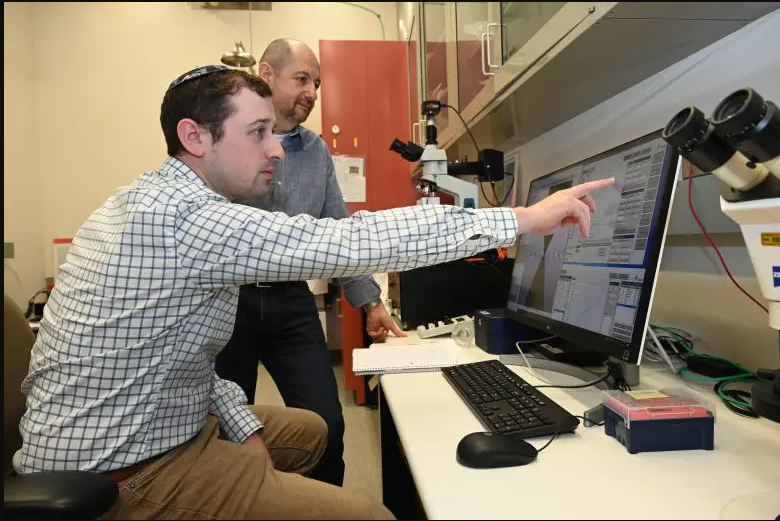

Oleg Gang, pictured behind, and Aaron Michelson use the specialized resources at CFN to measure the surprising strength of this novel material structure. Credit: Brookhaven National Laboratory

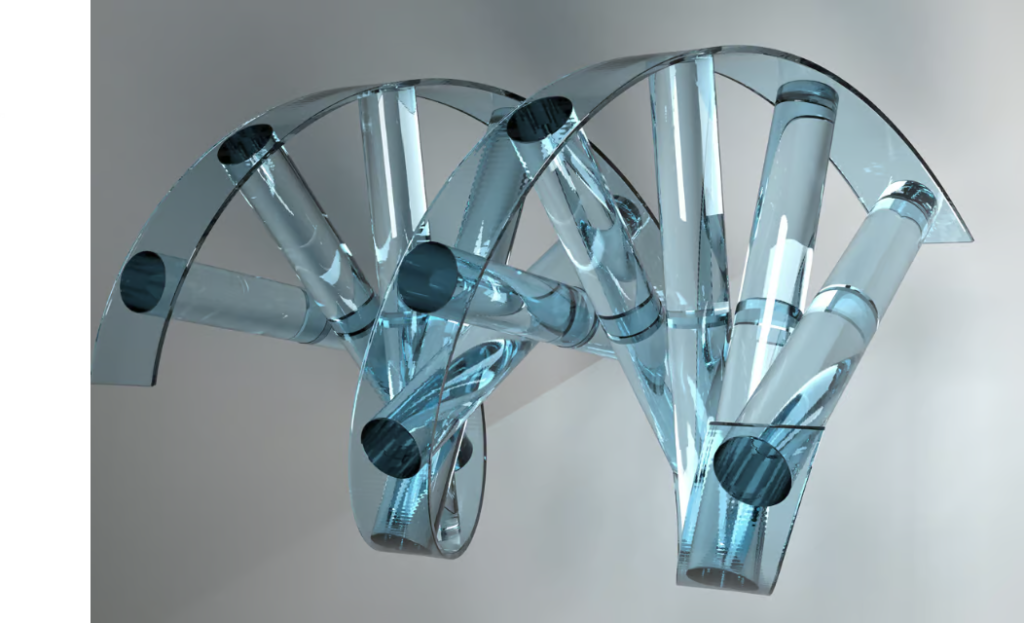

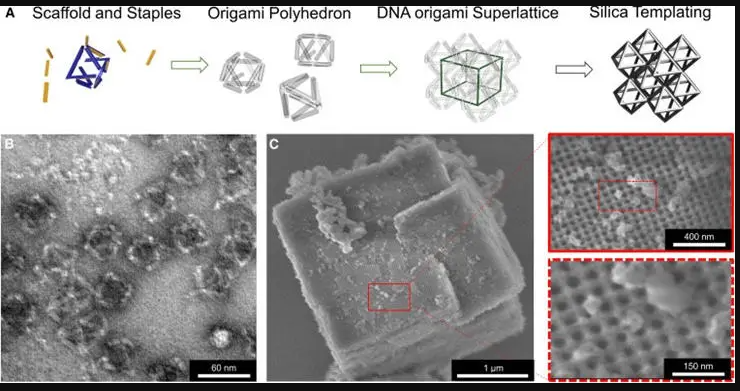

Gang previously collaborated on an experiment employing DNA structures to create a strong framework for innovative materials with the paper’s lead author, Brookhaven postdoctoral researcher Aaron Michelson. Interesting behaviours are displayed by DNA molecules. The bonding between complementary sequences is determined by the individual nucleotides, which are the building blocks of nucleic acids like DNA and RNA. Scientists have developed techniques to engineer the folding of DNA into specific shapes known as “origami,” called after the Japanese art of paper folding, thanks to the exact way they bind to one another. These DNA forms are addressable DNA linkages that can be used to instruct these nanoscale building pieces to “self-assemble.” This indicates that these origami DNA blocks can spontaneously construct precise structures with a repeating pattern.

Then, these building blocks adhere to one another to create a larger, repeating lattice. As shown by the team’s earlier investigations, this method enables the construction of 3D-ordered nanomaterials from DNA and the integration of proteins and inorganic nanoparticles. Gang, Michelson, and their colleagues were able to investigate what could be accomplished when that biomolecular scaffolding was utilised to make silica frameworks that preserve the scaffold architecture after learning how to comprehend and manage this special assembly process.

“We focused on using DNA as a programmable nanomaterial to form a complex 3D scaffold,” said Michelson, “and we wanted to explore how this scaffold will perform mechanically when transferred into more stable solid-state materials. We explored having this self-assembling material cast in silica, the main ingredient in glass, and its potential.”

Michelson won the Robert Simon Memorial Prize at Columbia University for his work in this area. His study of DNA frameworks has looked at a variety of features and uses, including superconductivity and mechanical properties. Michelson’s work continues to expand and grow as it absorbs new layers of knowledge from these fascinating investigations, much like the foundations he has built upon.

A microscopic peek of how these DNA strands form shapes that are built into larger lattice structures that are coated in silica. CFN, JEOL-1400 TEM, and Hitachi-4800 SEM. Credit: Brookhaven National Laboratory

The subsequent step in the production process was motivated by biomineralization, which is the process by which some living tissue generates minerals to make themselves tougher, like bones.

We were particularly eager to investigate how nanoscale structure may be used to improve the mechanical properties of common materials like glass.

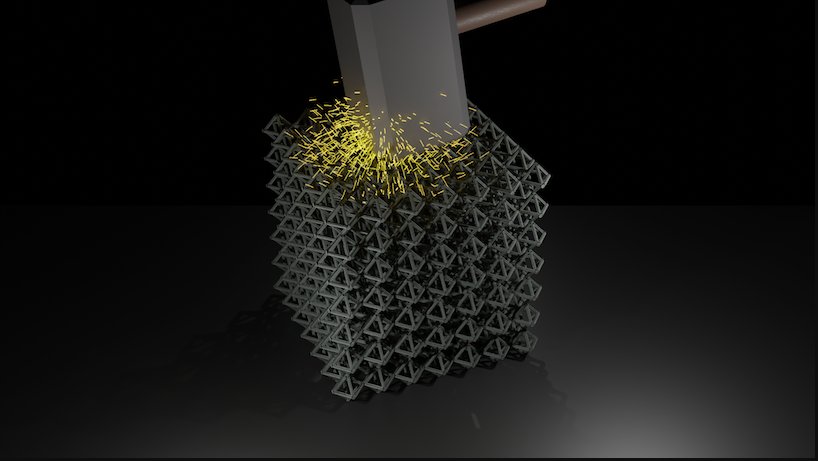

The DNA frames were coated with a very thin silica glass layer that was only a few hundred atoms thick (approximately 5 nm), leaving the interior spaces accessible and ensuring that the final substance is extremely light. On this small a scale, the glass is impervious to imperfections or flaws, offering a strength not found in bigger pieces of glass where cracks form and cause it to shatter. The crew was curious about the material’s exact strength.

Strength Under Pressure

There are easy techniques to determine whether something is durable. Observing their behaviour and prodding, pushing, and leaning on objects can frequently yield useful information. Under pressure, do they budge, creak, buckle, or maintain their stability? It is possible to grasp an object’s strength in this way even without the use of accurate measurement techniques. But how does one press on something that is too little to see?

“We used a technique called nanoindentation to measure the strength of these tiny structures,” said Michelson. “A precise device that can apply and detect resistive stresses is used in nanoindentation, a mechanical test on a very small scale. Because the thickness of our samples is so thin—a few microns, or a thousandth of a millimeter—these materials cannot be measured using standard techniques. We can quantify mechanical behaviour and see the compression process together using an electron microscope and nanoindentation.

A graph comparing the nanolattice in this experiment to the relative strength of various materials. Credit: Brookhaven National Laboratory

Researchers may analyse the sample’s mechanical properties when the tiny instrument compresses or indents it. When the sample’s original state is restored once the compression has been removed, they can see what happens to the substance. This crucial information can be saved in case the building ever fails or develops any flaws.

The DNA lattice with glass coating proved to be four times more durable than steel when put to the test! Even more intriguing was the fact that it had a density that was roughly five times lower. Although there are materials that are both strong and relatively light, it has never been accomplished to this extent.

This technique wasn’t something that was always readily available at CFN, however

Seok-Woo Lee, an associate professor at the University of Connecticut with knowledge of the mechanical properties of materials, was a collaborator with us, according to Gang. He was a CFN user who took advantage of some of our tools and resources, such as electron microscopes, and that’s how we got to know him. We didn’t have the ability to perform nanoindentation at first, but he helped us find the correct resources and set us on the right path. Another illustration of the advantages of collaboration between academic scientists and researchers in federal laboratories. These resources and the knowledge are now available for us to advance research like this.

Building Something New and Exciting

Materials scientists still have reasons to be optimistic about what this means moving forward, even though there is a lot of work to be done before scaling up and considering the countless possibilities for such a material. Even stronger than glass materials like carbide ceramics will be examined by the researchers to understand how they function and behave. This might eventually result in lightweight materials that are even more durable.

Despite the fact that his profession is only in its infancy, Michelson has already accomplished a great deal and is anxious to begin the next stages of his studies.

“It’s a wonderful opportunity to be a postdoc at Brookhaven Lab, especially after being a Columbia University student who would work at the CFN quite often,” recalled Michelson. “This is what led me to continue there as a postdoc. The capabilities that we have at the CFN, especially in regard to imaging, really helped to propel my work.”

Reference: “High-strength, lightweight nano-architected silica” by Aaron Michelson, Tyler J. Flanagan, Seok-Woo Lee and Oleg Gang, 27 June 2023, Cell Reports Physical Science.

DOI: 10.1016/j.xcrp.2023.101475